sheet metal drawing operation is used to make

You can use embossing to stiffen metal panels or. Drawing is a sheet metalworking operation used to produce.

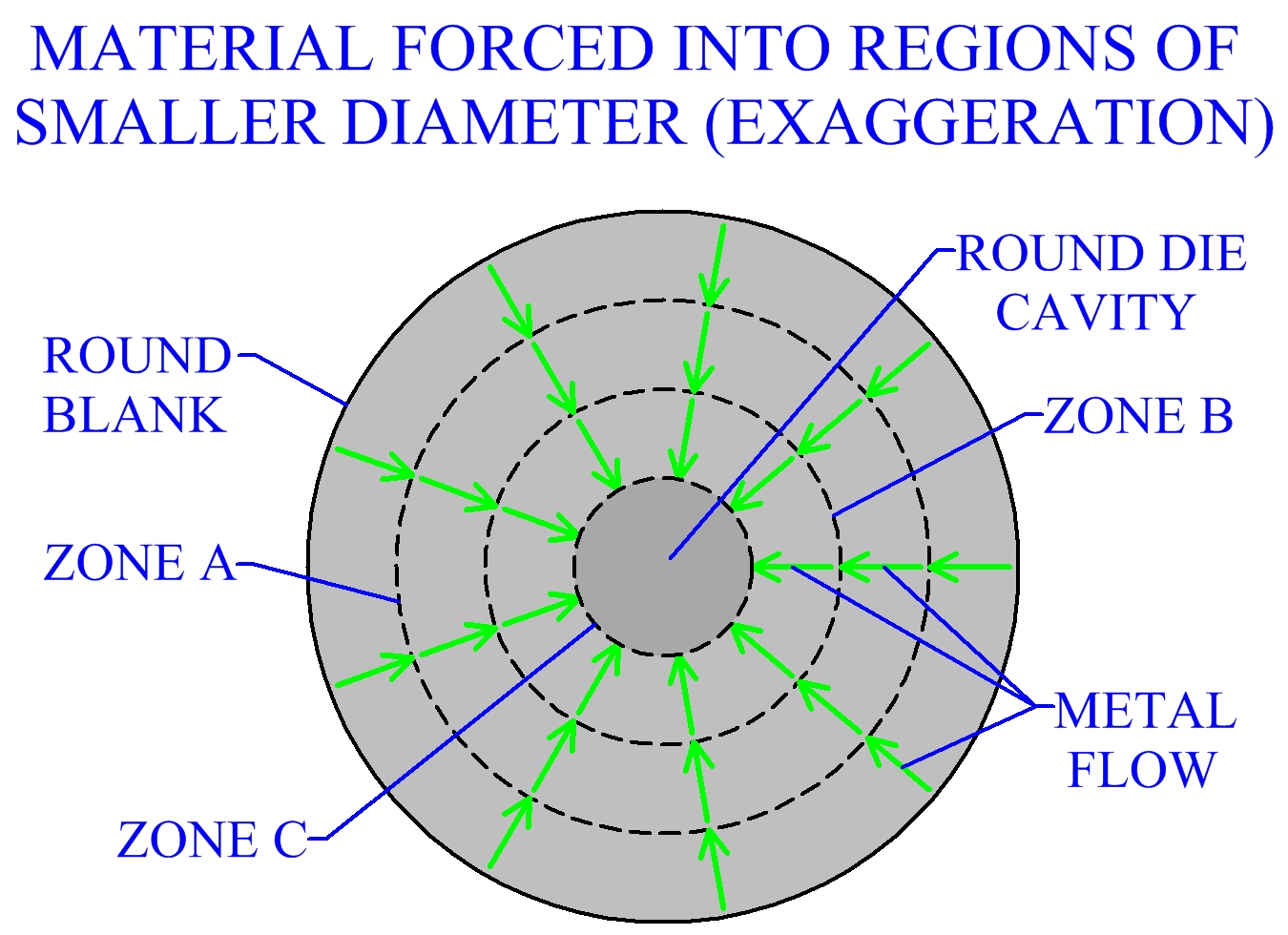

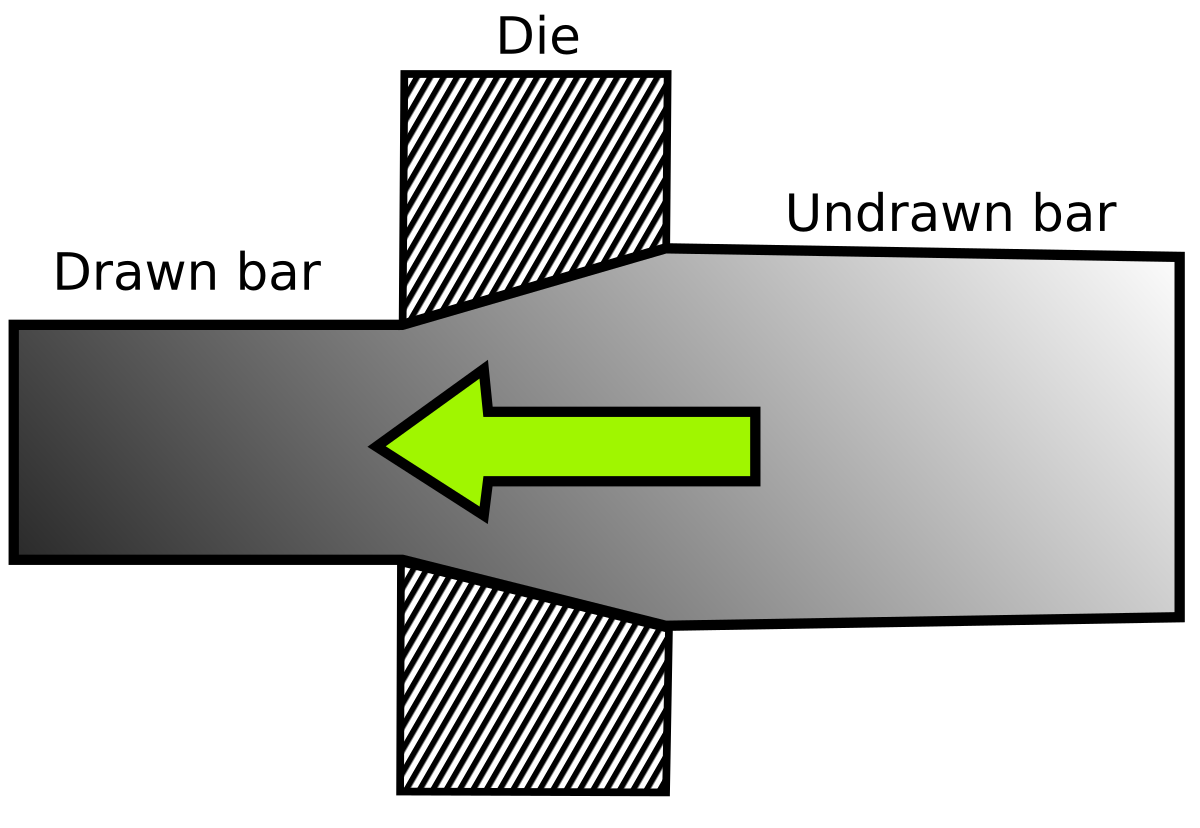

In manufacturing metal drawing process is used to manufacture parts of different cross sections like circular square rectangular as well as other cross sections.

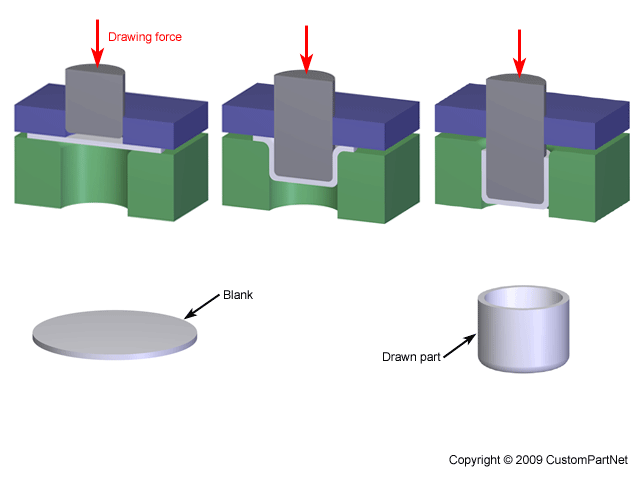

. Drawing sheet metal forming operation used to make cup shaped box shaped or other complex curved hollow shaped parts performed by placing a piece of sheet. Drawing is a sheet-metal-forming operation used to make cup-shaped box-shaped or other complex. Mechanical Engineering questions and answers.

School Atmiya Institute Of Technology. This process is very extensively used in the automobile industry to. Embossing is a sheet metal operation performed using matching male and female dies and the depth of metal drawn is less.

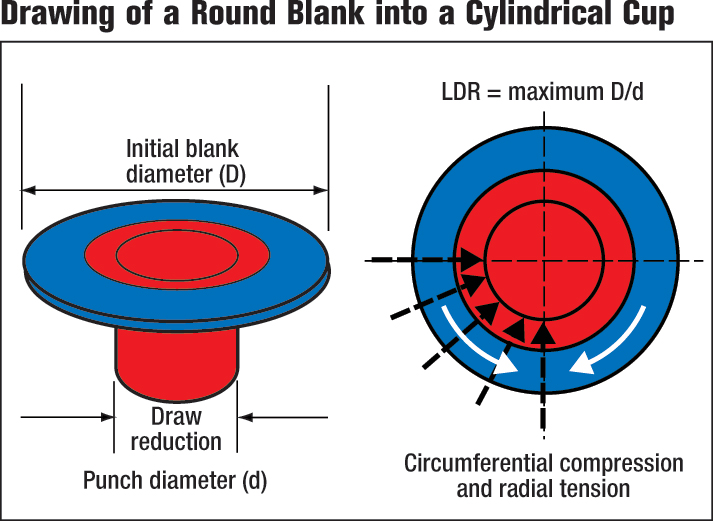

Punching Operations A punch and die technique is used to create circular holes in a sheet of metal. The drawing operation results in the reduction in cross-sectional area of the material by increasing its length. Hi FriendsIn this video you will learn Types of Drawing operations in sheet metal Common Defects in drawing operationRedrawingReverse redrawingDefects in.

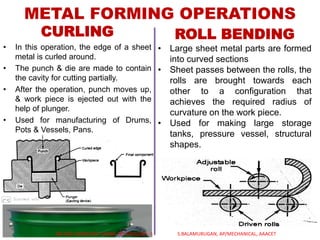

Sheet metal is metal formed into thin flat pieces usually by an industrial process. Pots and pans for cooking containers sinks automobile parts. For this type of sheet metal operation a punch and die are used.

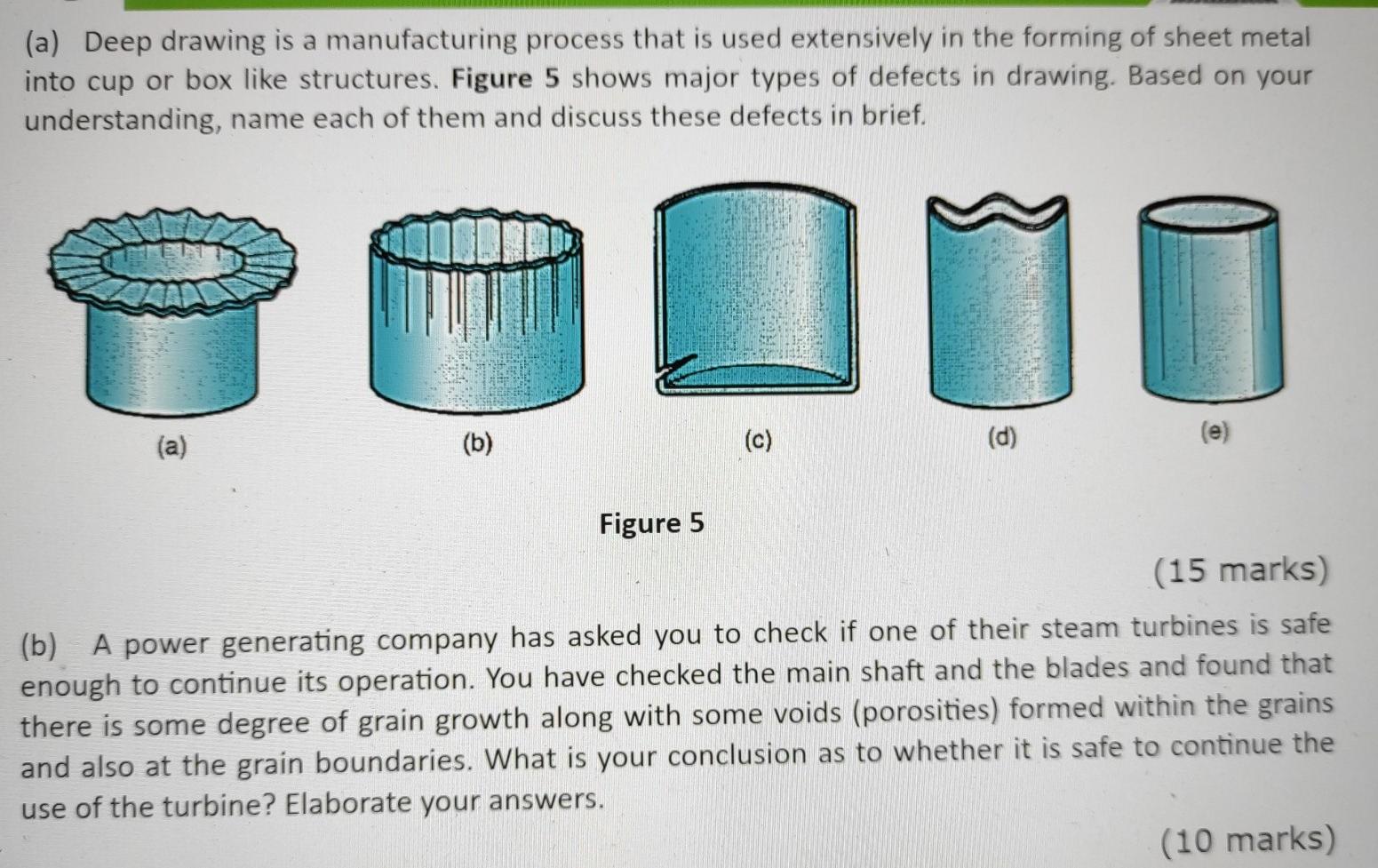

Deep drawing is a manufacturing process that is used extensively in the forming of sheet metal into cup or box like structures. Sheet metal is one of the fundamental forms used in metalworking and it can be cut and bent into a variety of. The deep drawing process is used to manufacture sheet metal parts in large volumes for various industries.

Drawing is a metalworking process that uses tensile forces to stretch elongate metal glass or plastic. Sheet metal Drawing Operation involves drawing sheet metal parts in a cup-like shape by utilizing a bending press. Drawing is classified into two types.

What is the name. Sheet metal drawing operation is used to make A wire B tube C cup shaped parts D. Terms in this set 19 Identify the three basic types of sheet metalworking operations.

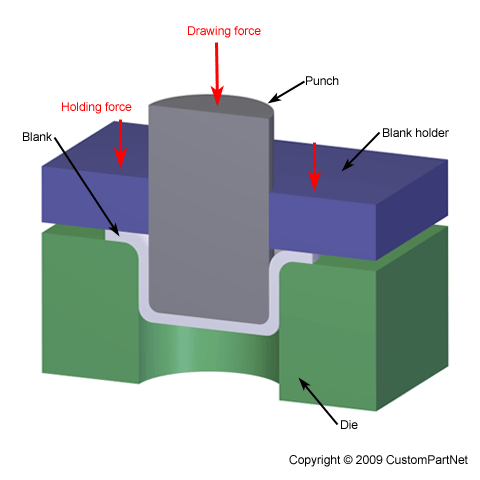

As the metal is drawn pulled it stretches to become thinner to achieve a desired. In conventional sheet metalworking operations a. Sheet metal drawing is a metal forming operation in which the metal blank is stretched into a desired shape by the mechanical action of a punch.

Sheet metal drawing operation is used to make a wire. Sheet metal drawing and wire. Figure 3-67 sheet metal drawing without blankholder.

The draw die must have the shape of a funnel or cone to permit the sheet metal to be drawn properly into the die cavity.

Key Design Principles For Successful Deep Drawing

Deep Drawing An Overview Sciencedirect Topics

Deep Drawing Operation With Diagram Press Working

Solved A Deep Drawing Is A Manufacturing Process That Is Chegg Com

Deep Drawing An Overview Sciencedirect Topics

Deep Drawing From A To Z Metalforming Magazine Article

Understanding Sheet Metal Operations With Diagram Student Lesson

What Is Metal Stamping Aranda Tooling Metal Stamping 101

Deep Drawing An Overview Sciencedirect Topics

Ise 311 Sheet Metal Forming Lab Cup Drawing In Conjunction With Section 20 3 In The Text Book Fundamentals Of Modern Manufacturing Third Edition Mikell Ppt Download

Deep Drawing Operation In Sheet Metal Smlease Design

Deep Drawing An Overview Sciencedirect Topics

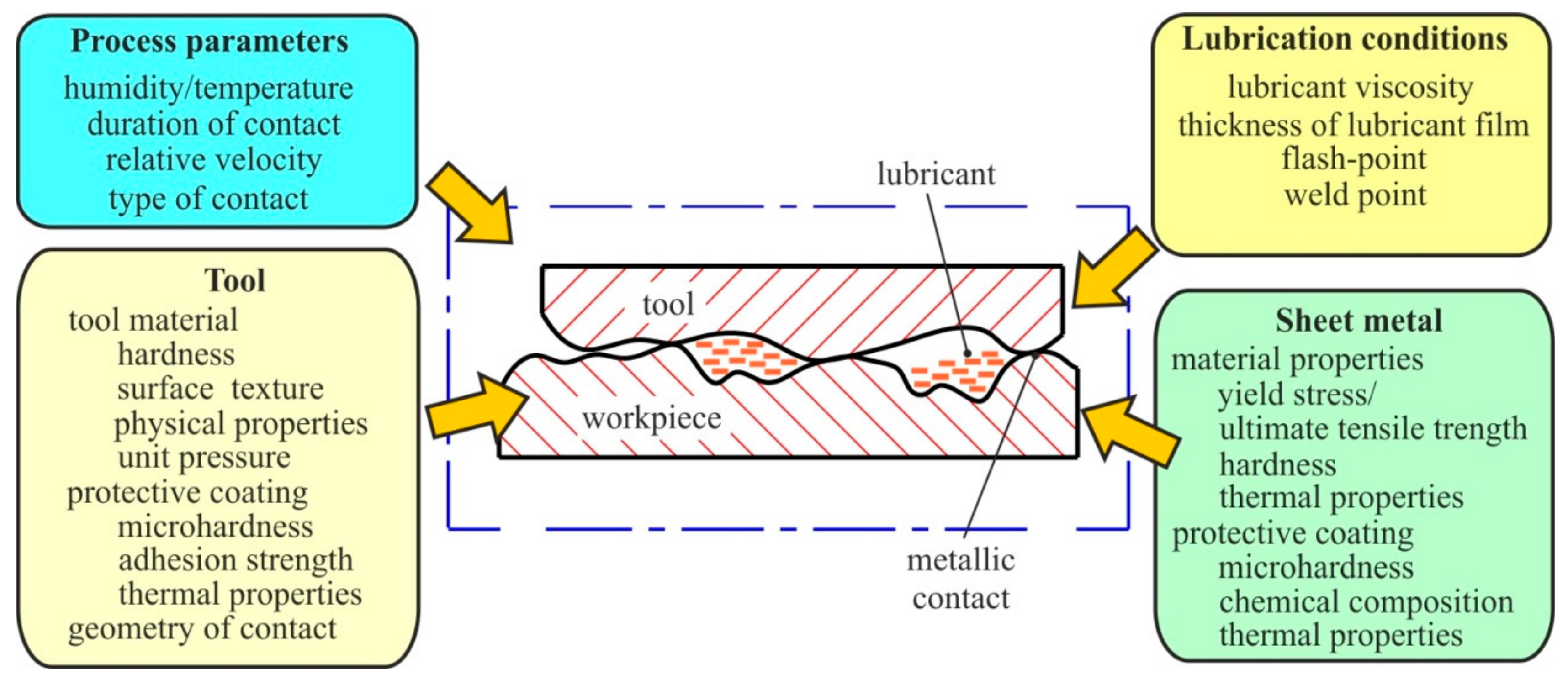

Metals Free Full Text Recent Developments And Trends In The Friction Testing For Conventional Sheet Metal Forming And Incremental Sheet Forming Html

Solved Drawing Is A Sheet Metal Forming Operation Used To Chegg Com